Insights

Elsys • The Tech Insider

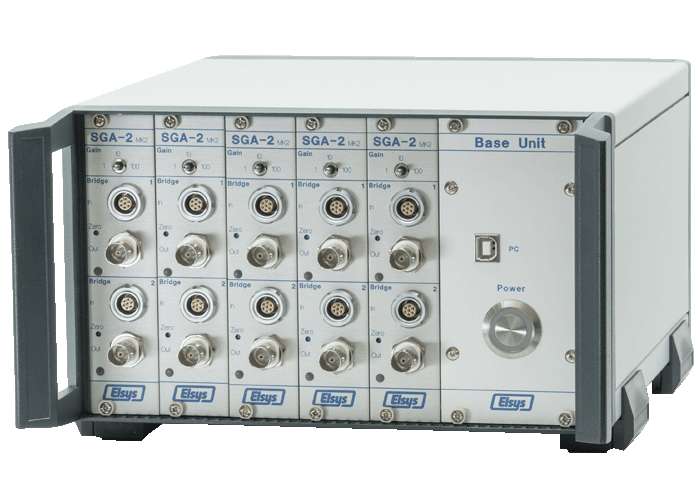

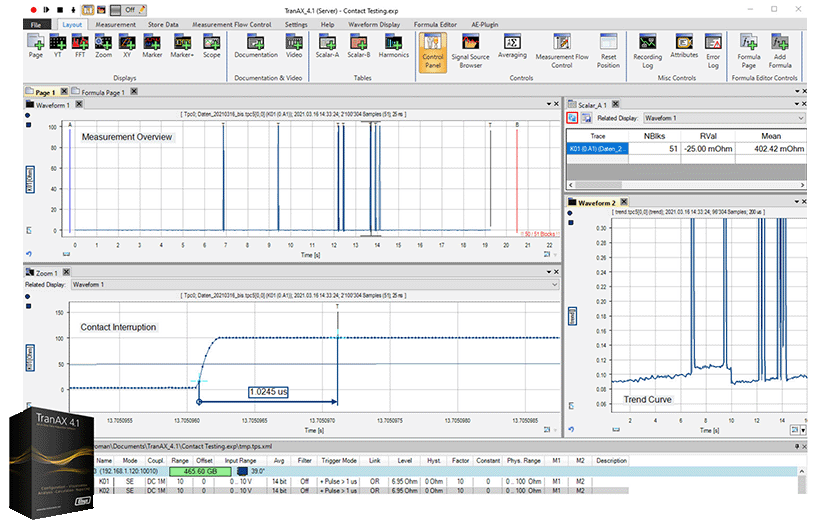

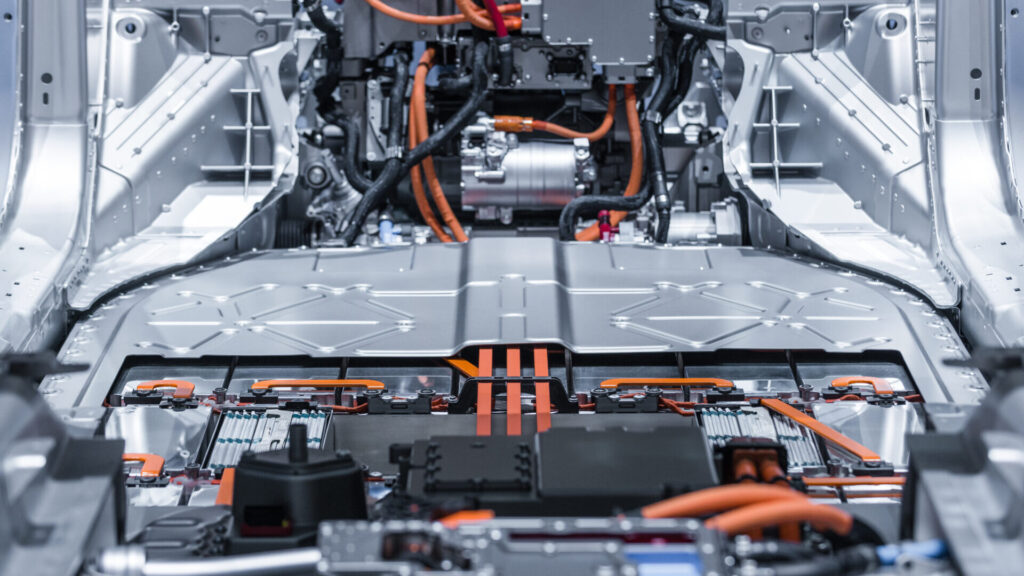

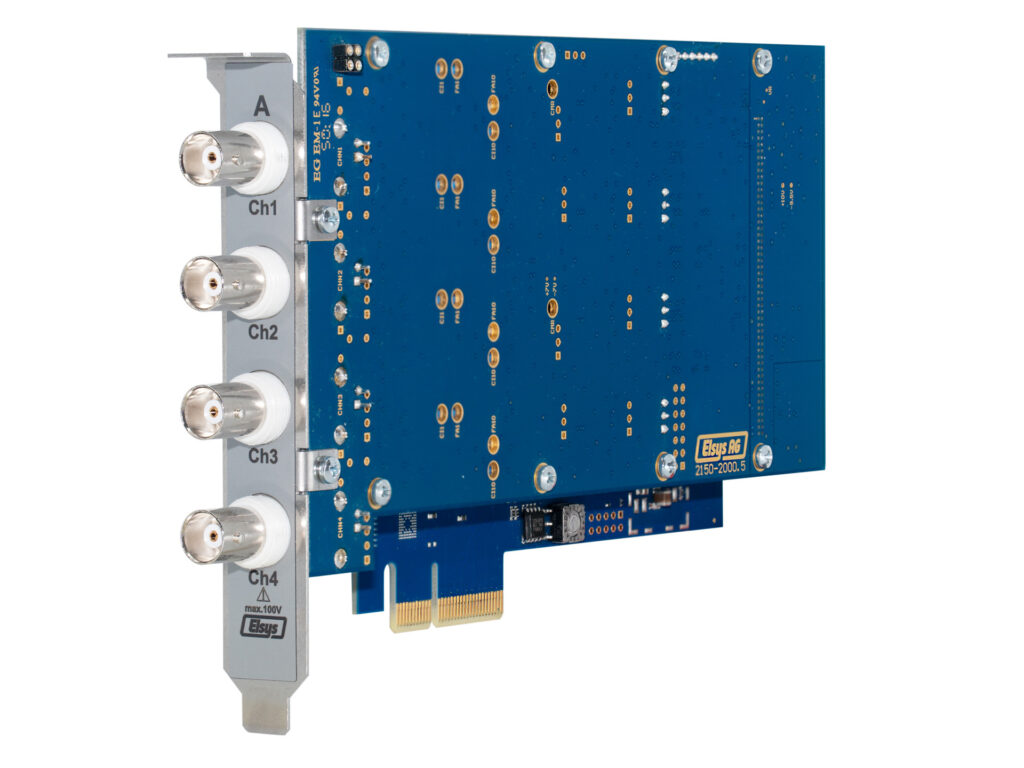

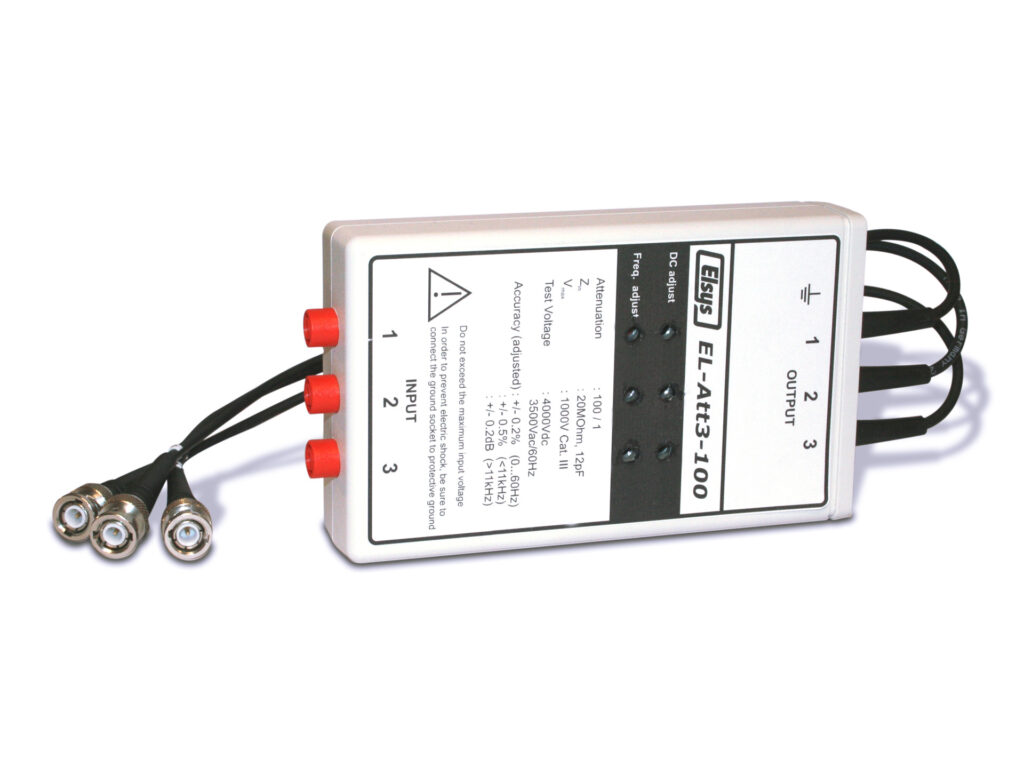

Contact Testing for Reliable Car Electronics

Learn more about how our TraNET EPC-GN data acquisition device is used to test connectors for the automotive industry, increasing the reliability of automotive electronics.

Elsys • The Tech Insider

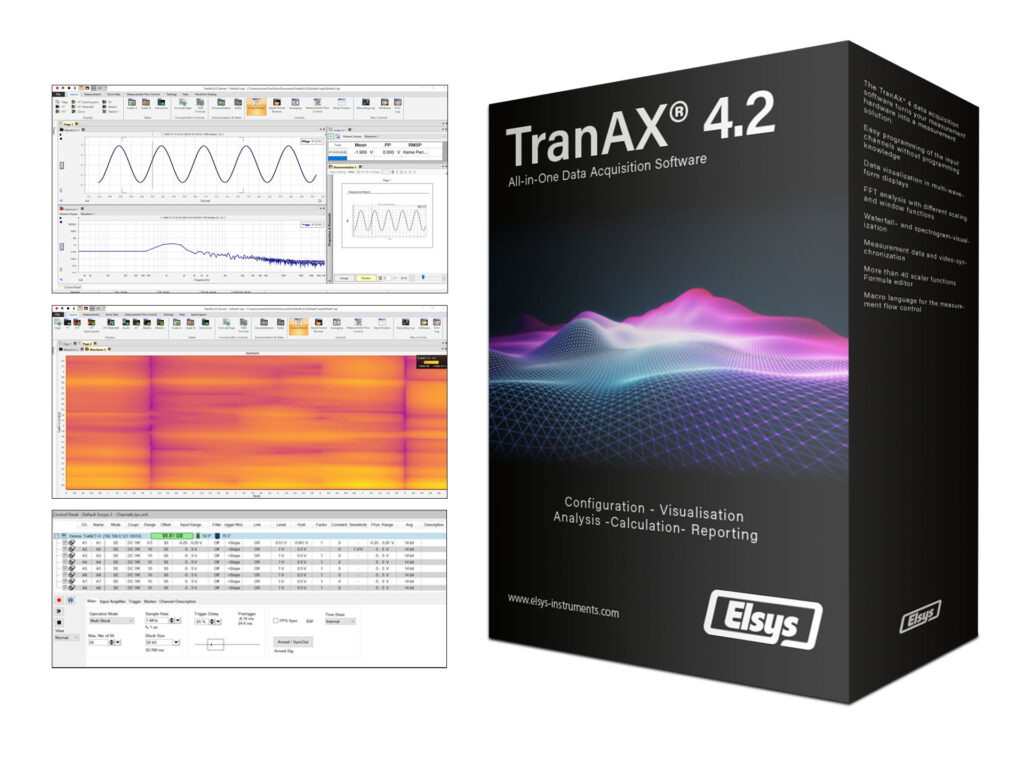

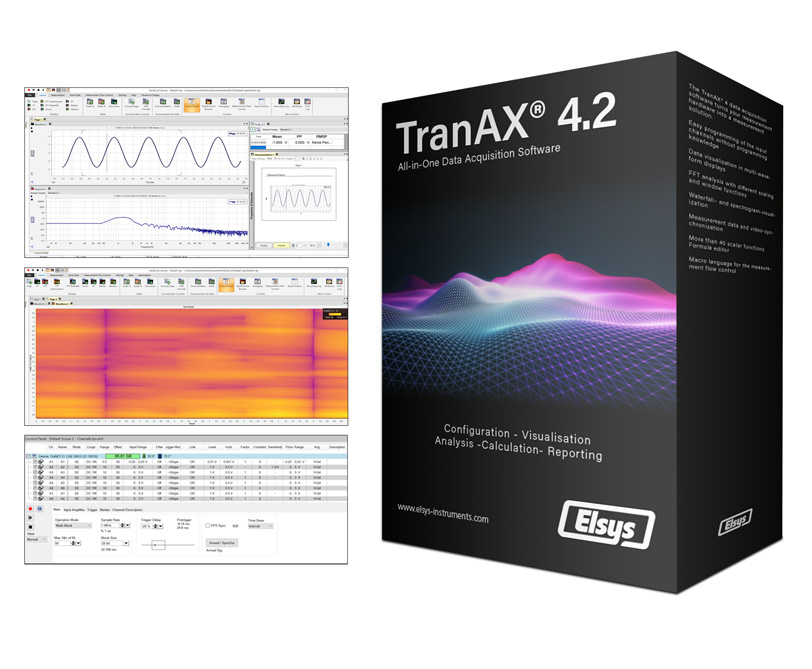

The next version of TranAX is available

TranAX 4.2 offers new possibilities for data visualization and post-processing.

The spectrogram as well as the waterfall diagram enable new display variants for frequency analyses. In addition, the new integration of Python code in the formula editor allows even more possibilities for data analysis or automation.